Electrode Cap and Tip

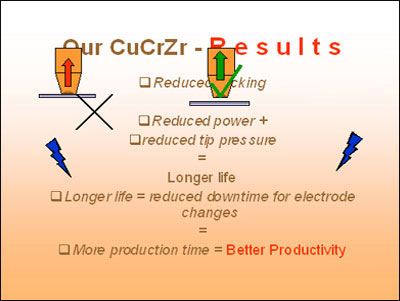

CuCrZr material is best suited material of spot welding caps for both coated & non-coated sheets. The additional cost advantages of our (CuCrZr) Cap, Tip and Shank and Adaptor:-

- • RWMA – class 1 copper chromium zirconium (CuCrZr), Conductivity 85% and Hardness 83B.

- • Does not stick on Zr coated materials because the lower welding current and pressure used melt less of the Zr and thus reduce the diffusion of the Zr into the Cu.

- • Reducing the current by 15 - 20%, which is a big saving of energy & power consumption.

- • Reducing weld force by which weld splatters are minimized.

- • Reducing dressing time to more than half that also if necessary, as the cap tip surface

does not allow formation of any contamination like brass coating / carbon. - • Reduce cap changing downtime.

- • Better weld quality.

- • Increasing Kickless & Aid Cable life.

These above factors ultimately results into more productivity.

Our pursuit of perseverance to register ourselves amidst the elite companies in this domain encourages us to manufacture and supply a commendable range of Weld Gun Arm. These have minimum rockwell hardness of 90B and a minimum electrical conductivity of 45% IACS. Offered products are made available in scores of designs and sizes to meet the diverse needs of the clients. Manufactured at our production unit, the offered products are properly tested before delivering to clients.

Features:

We are the top manufacturers and suppliers of a supreme quality range of Electrodes Caps, Electrodes Components, Gun Arms And Holders, Seam Welding Wheels, Holders For Stationary Welding Machine, Jumper And Kickless Cables, Electrical Shunts and many more. These products are manufactured by our skilled professionals using the finest grade raw material, which is procured from trustworthy vendors of the industry.

Further, these components are widely treasured by our clients due to their features like high durability, dimensional accuracy, robust construction, excellent strength and fine finish. The offered components are available in different specifications and can also be customized as per the diverse requirements of our esteemed customers.

Fabricated electrode arms are manufactured for electrode sizes of Ø 100-800mm for UHP-furnaces, AC-electric arc furnaces, DC-electric arc furnaces and ladle furnaces.

Fabricated electrode arms are manufactured for electrode sizes of Ø 100-800mm>Due to their outstanding design and optimal materials, our electrode arms deliver lower electric operating costs, low graphite consumption, higher process speed, easy handling, optimal symmetry and maximum efficiency.

Current Conducting Copper / Steel Electrode Arms

Current conducting electrode arms are a melt shop proven design that provide efficient cooling as well as reduced electrical loss. The utilization of the copper clad (copper & steel) arms combines the high strength of steel with the high conductivity and current carrying ability of copper.

Typical Copper Grades and Copper Alloys

Advantages of Copper/Steel Electrode Arms

Current Conducting Aluminum Electrode Arms

Lighter aluminum current conducting electrode arms are available if less stress for the mechanical system is required. The weight advantage of aluminum electrode arms are optimal for modernization of existing furnaces, with less need for changing peripheral structural components.

Conventional Steel Electrode Arms

CHROMIUM ZIRCONIUM COPPER SPOT WELDER CAPS

- 1. This is the basic cap material having a composition of 1% Chromium, 0.1% Zirconium; balance Copper – nominal.

- 2. The nominal hardness of a cold forged Chromium Zirconium Copper cap is 85HRB, which results in long working life of the cap.

- 3. The Zirconium in the cap prevents brassing up during welding of galvanized steels.

- 4. Since it is Mipalloy’s most popular cap material, standard designs are always available ex stock off the shelf.

- 5. It is the lowest cost spot welding cap material.

- 6. Chromium Zirconium Copper has a large application window and

can be used for welding majority of jobs including plain Cold rolled and cold annealed steels,galvanized steels, Nickel steels and Terne coated steel sheets. - 7. Chromium Zirconium Copper is designated Mipalloy 3ZR.

- 8. Other international nomenclature include.