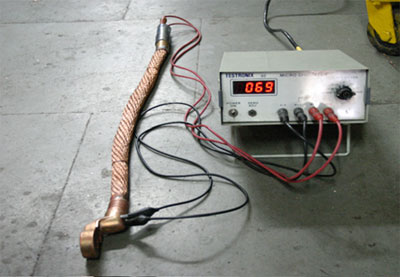

Water Cooled Sub / Jumper Cable Manufacturer & Exporter

Excellent cooling effect even in continued welding operation.

Water Cooled Jumpers (WJ) come equipped with full length filter tubes, to insure the free flow of water through the entire cable. Bending or kinking will not reduce water flow.

To order cables you need to determine: 1] Type of end 2] Cable Gauge 3] Length

A chart for sizing the correct gauge cable is on the right of the page, as well as guidelines for installation.

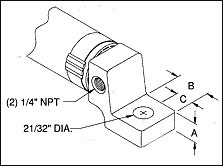

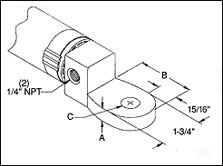

| Type B | |||

MCM |

A |

B |

C |

350/400 |

9/16″ |

1-15/16″ |

9/16″ |

500/600 |

9/16″ |

1-15/16″ |

5/8″ |

750 |

5/8″ |

1-3/8″ |

11/16″ |

1000 |

3/4″ |

1-1/2″ |

3/4″ |

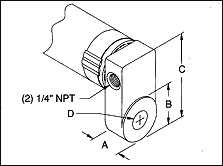

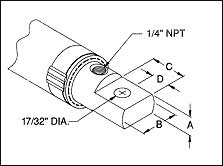

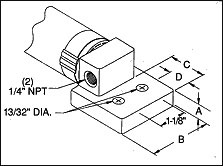

| Type B - 2 | ||||

MCM |

A |

B |

C |

D |

350/400 |

11/16″ |

1-1/16″ |

2-11/16″ |

17/32″ |

500/600 |

13/16″ |

1-3/8″ |

2-7/8″ |

17/32″ |

750 |

13/16″ |

1-5/8″ |

3-1/8″ |

21/32″ |

1000 |

15/16″ |

1-7/8″ |

3-1/4″ |

21/32″ |

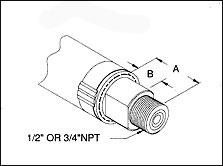

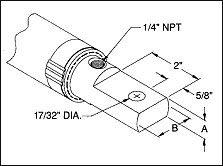

| Type B-4 | ||

MCM |

A |

B |

350/400 |

1-3/8″ |

1/2″ |

500/600 |

1-7/8″ |

5/8″ |

750 |

1-7/8″ |

5/8″ |

1000 |

2″ |

11/16″ |

| Type B - 5 | ||||

MCM |

A |

B |

C |

D |

350/400 |

9/16″ |

1-1/8″ |

1-1/4″ | 1/2″ |

500/600 |

5/8″ |

1-1/4″ |

1-3/8″ | 5/8″ |

750 |

5/8″ |

1-3/8″ |

1-3/8″ | 5/8″ |

1000 |

5/8″ |

1-5/8″ |

1-3/8″ | 5/8″ |

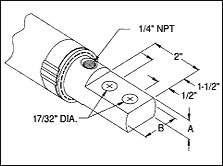

| Type B-6 | ||

| MCM | A | B |

| 350/400 | 9/16″ | 1-1/8″ |

| 500/600 | 5/8″ | 1-1/4″ |

| 750 | 5/8″ | 1-3/8″ |

| 1000 | 5/8″ | 1-5/8″ |

| Type B-6 2Hole | ||

MCM |

A |

B |

350/400 |

9/16″ |

1-1/8″ |

500/600 |

5/8″ | 1-1/4″ |

750 |

5/8″ | 1-3/8″ |

1000 |

5/8″ | 1-5/8″ |

| Type B-7 | ||

MCM |

A |

B |

350/400 |

9/16″ |

1-1/8″ |

500/600 |

5/8″ | 1-1/4″ |

750 |

5/8″ | 1-3/8″ |

1000 |

5/8″ | 1-5/8″ |

| Type B-7 | |||

MCM |

A |

B | C |

350/400 |

9/16″ |

2-1/8″ | 17/32″ |

500/600 |

9/16″ | 2-1/8″ | 17/32″ |

750 |

9/16″ | 2-5/16″ | 21/32″ |

1000 |

5/8″ | 2-3/8″ | 21/32″ |

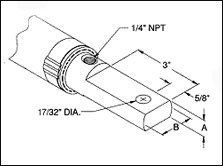

| Type B-11 | ||||

MCM |

A |

B | C | D |

350/400 |

3/8″ | 2″ | 1-1/8″ | 9/16″ |

500/600 |

3/8″ | 2″ | 1-1/8″ | 9/16″ |

750 |

5/8″ | 2-1/2″ | 1-1/2″ | 7/8″ |

1000 |

3/4″ | 2-1/2″ | 1-1/2″ | 7/8″ |

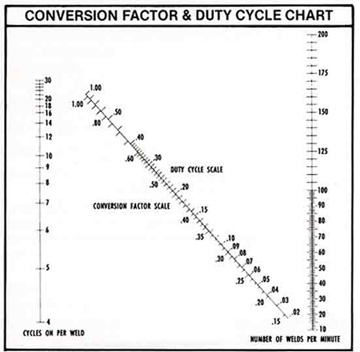

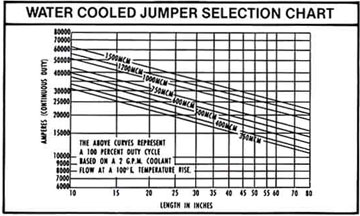

Use the following method to determine what size cable should be used for your application. First you use the Conversion Factor chart to determine your “Continuous Duty Current”; then you read the correct size cable off the second chart. An example is worked out below.

Example Data :

Good Working shapes for Water Cooled Cables

Installation Guidelines

How to install water cooled cablesWater cooled jumpers should always be installed with a bend radii ranging from 90° to 180°. See the chart below for the minimum recommended radii.

It should be noted that jumper life is inversely related to the operating temperature of the cable; the higher the temperature the shorter the life. The recommended operating temperature is 131°F (55°C) or less, and the maximum operating temperatures should not exceed 158°F (70°C). Making sure there is enough water flow is critical for insuring a low operating temperature.

Recommended Minimum Bend Radii :

Minimum Distance from the end of the hose to the point where the bend radii should start is :

More Specifications

D.C. Resistance of Single Conductor Water Cooled

(and Air Cooled) Cables

| MCM | D.C. Resistance |

| (Ohms per foot at 70 °C) | |

| 350 | .0000376 |

| 400 | .0000322 |

| 500 | .0000263 |

| 600 | .0000217 |

| 750 | .0000172 |

| 1000 | .0000130 |

| 1200 | .0000110 |

| 1500 | .0000088 |

| 2000 | .0000066 |

Recommended Minimum Gallons/min